|

We met in Cary so we could drive to the mountains together. Sue came in from Connecticut (she had planned to fly, but had to drive because her flight was cancelled) and Jackie came up from Pinehurst). We packed up the car and headed out on our road trip with no real idea of what to expect.

The Folk School was founded in 1925. It offers year-round 5-day and weekend classes on a large variety of topics including music, arts, crafts, and some unexpected subjects. During the week that we were there, 140 people attended classes in weaving, nuno felting, enameling, jewelry making, Italian cooking, writing, mandolin playing, wood turning, wooden mantle carving, blacksmithing, watercolors, chair caning, woodworking, and book arts. Classes actually began on Friday evening after registration and dinner in the dining room. After that we had daily class for four days each morning and afternoon with optional sessions in the evening after dinner. We were treated to stories and music at Morning Song each day before breakfast. All meals were served in the dining room. There were many optional activities at all times of the day including morning walks, tours of the campus and studios, chair massages, clogging demonstrations, contra dances, and the list goes on.

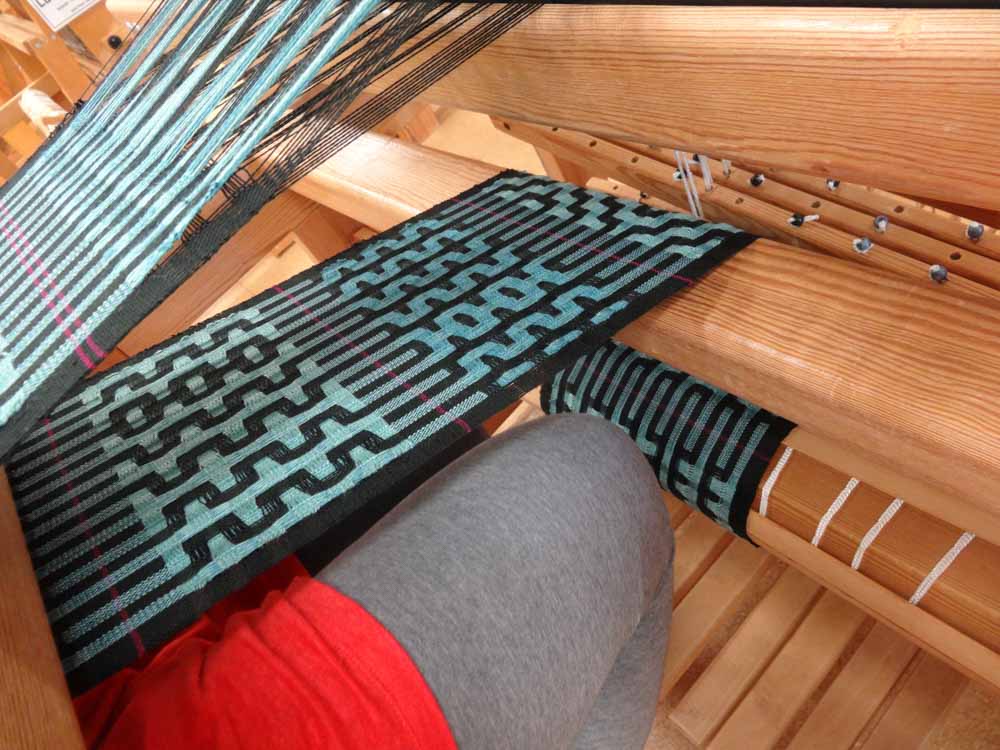

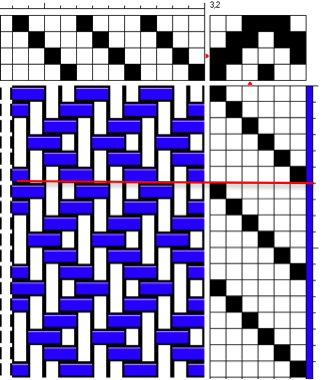

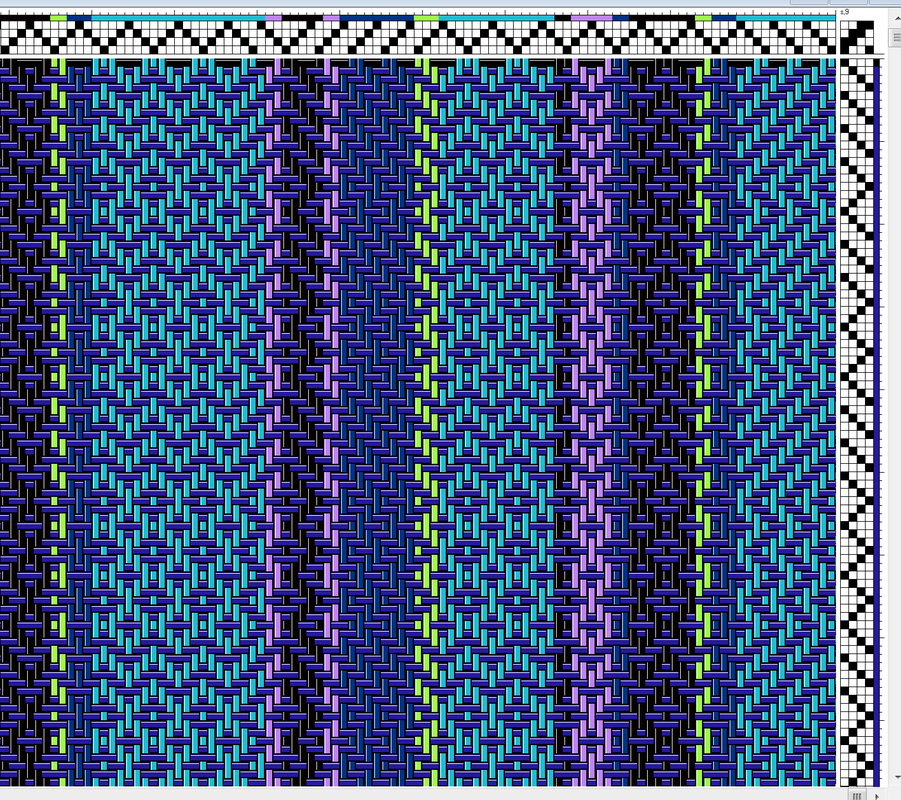

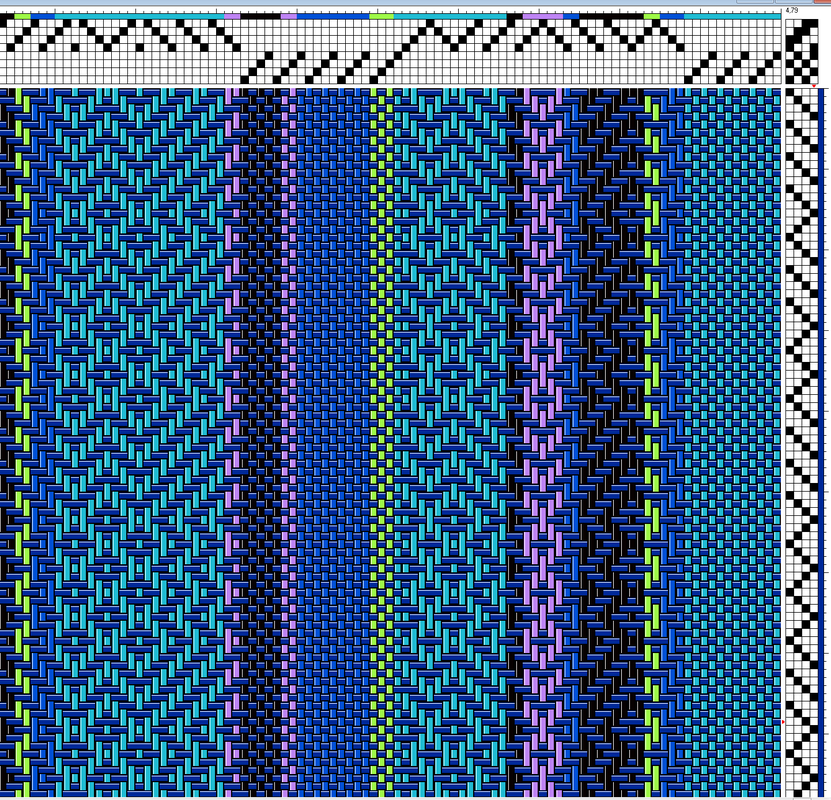

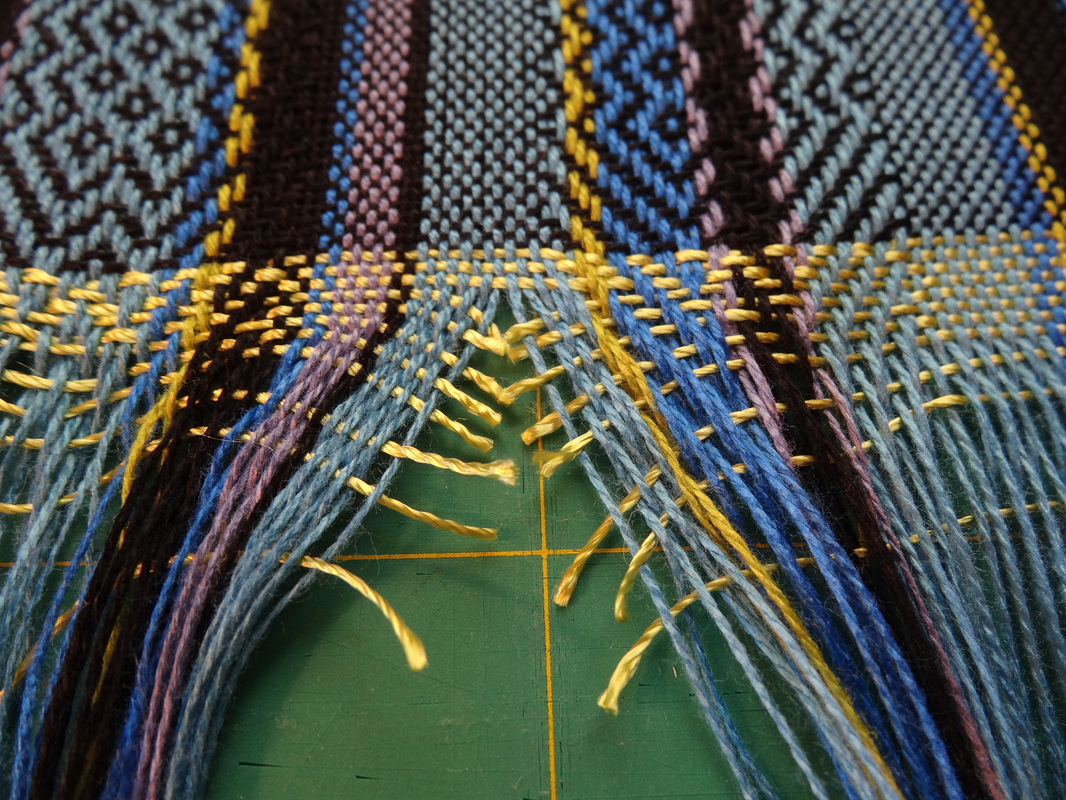

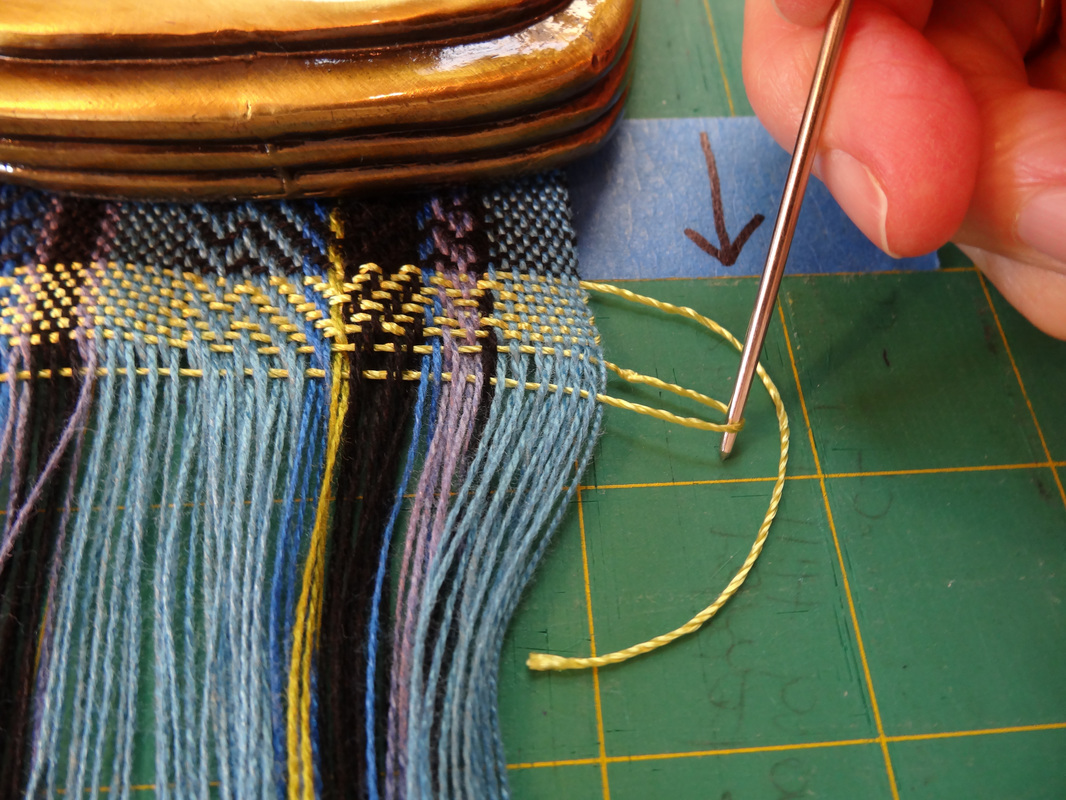

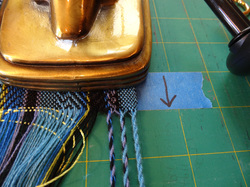

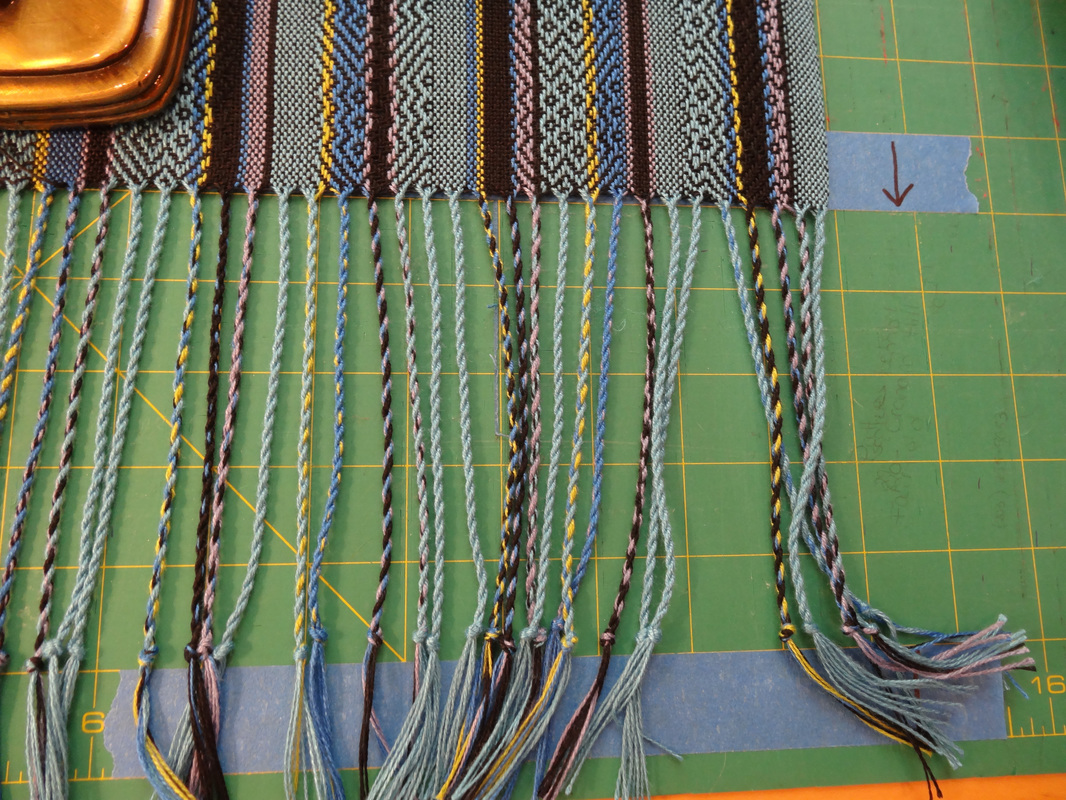

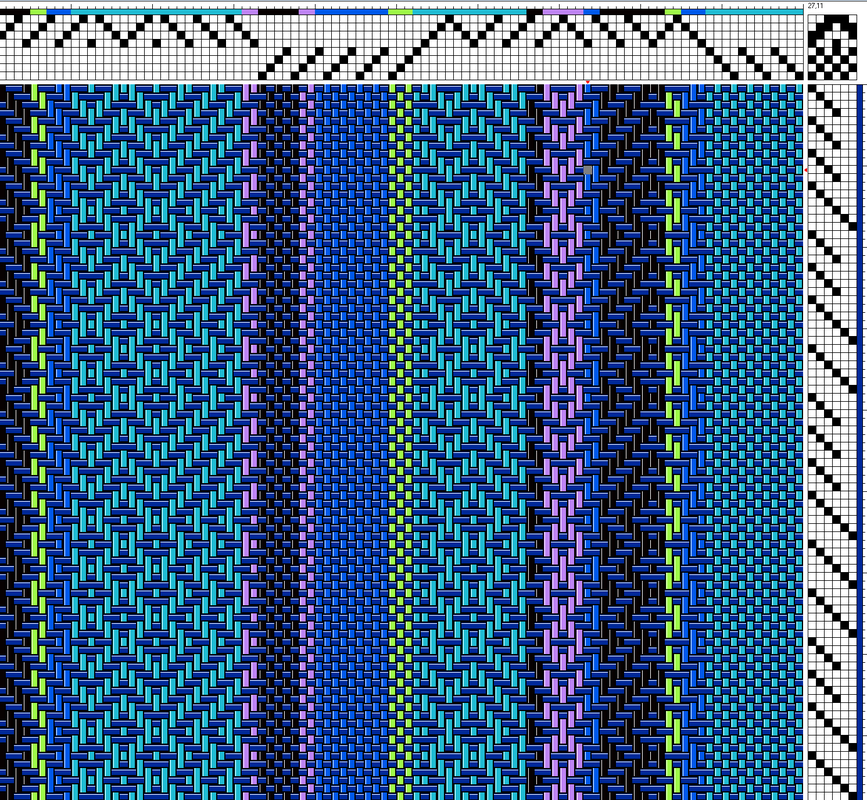

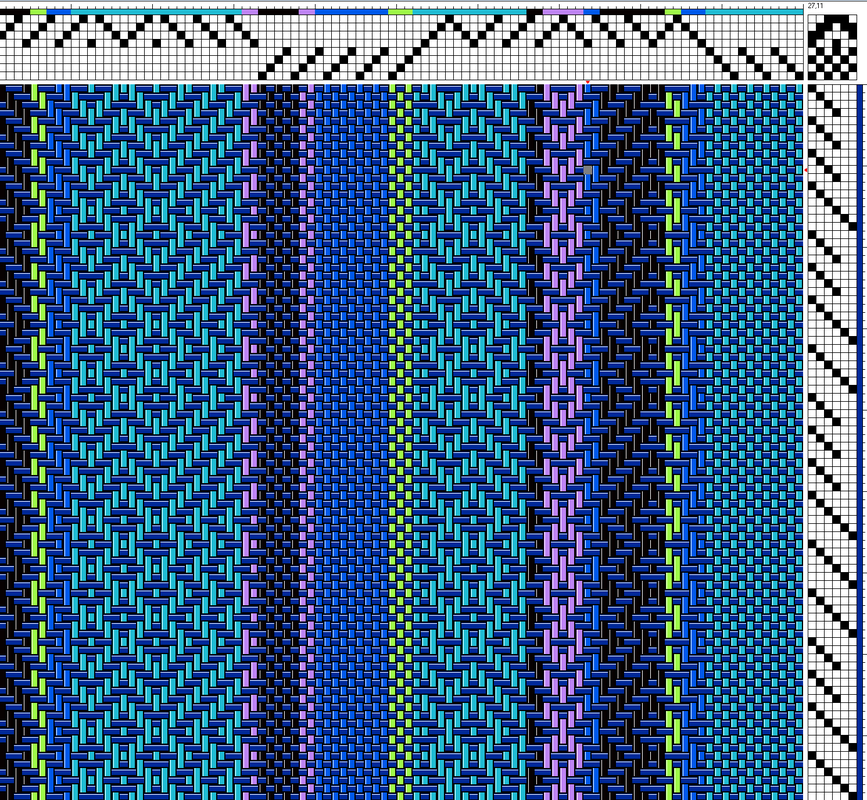

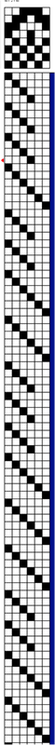

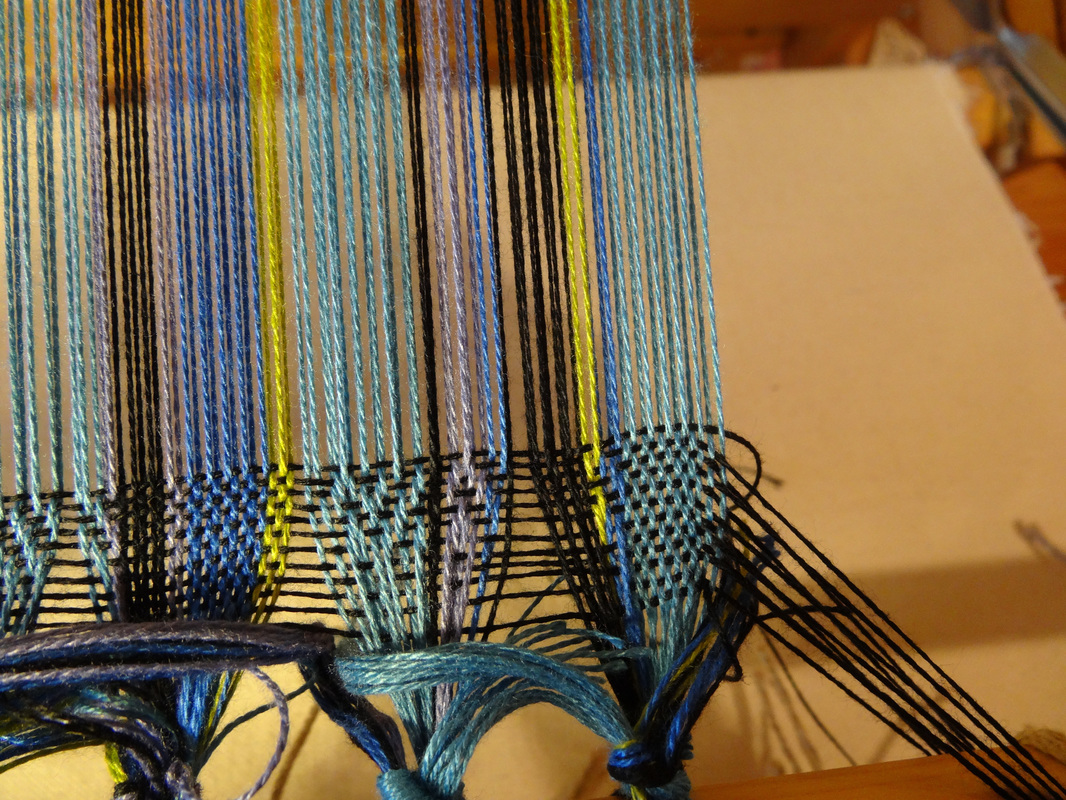

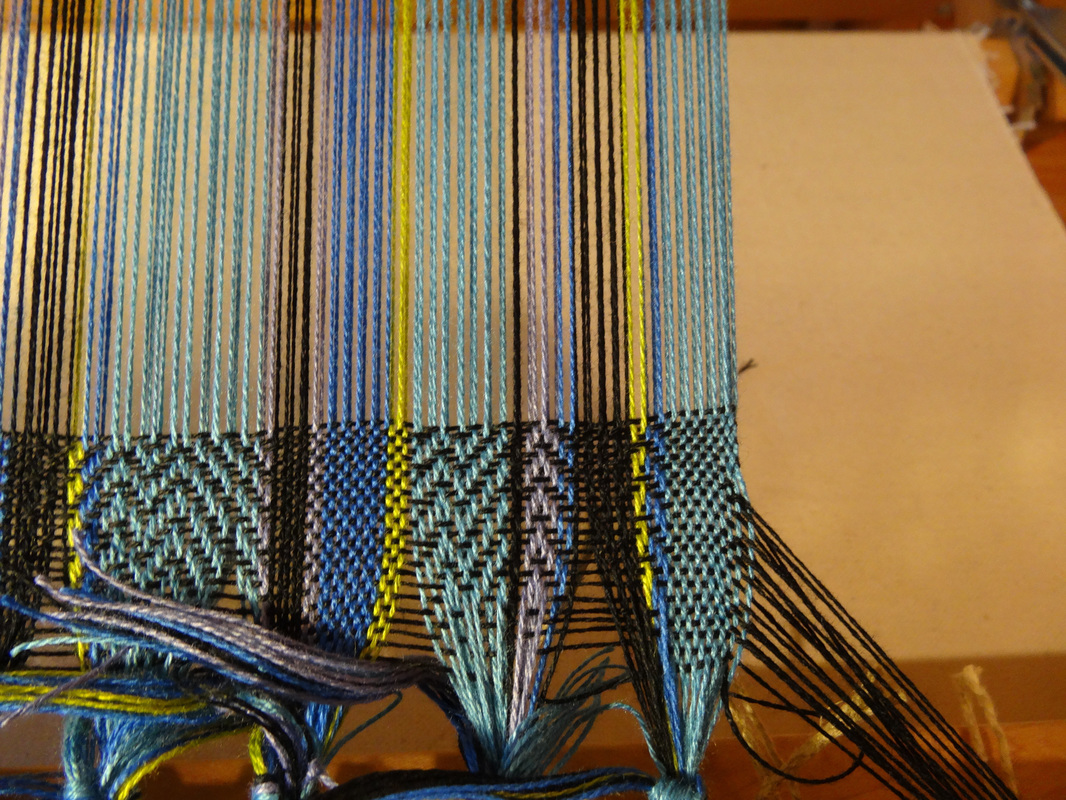

The best part, however, was the class itself. None of us knew anything about deflected doubleweave. Lisa (Elisabeth) Hill was a wonderful, generous instructor. She came with 2 tables full of yarn for us to use, pre-wound warps for anyone that chose to use them. We used gorgeous tencel, silk and wool, alpaca and silk, and merino yarns to warp our looms with beautiful 6-yard long warps that were 10” wide. We had a 2 part mission: weave a sampler and weave a scarf! Our first assignment was to weave a nice long sampler using 2 different treadlings and a total of about 16 different treadlings. We cut the samplers from the loom and washed and dried them so we could which decide which treadlings to use for a scarf. Decisions made, we tied back on and wove our scarves. We had time to twist our fringe, wash and dry (or almost dry) our scarves so they would be ready for the big presentation on Friday before everyone went home. Thirteen scarves, thirteen completely different threadings and colorways. (Number thirteen was woven by Lisa’s pretty wonderful assistant, Lillian). Pretty amazing results!

0 Comments

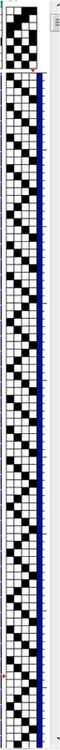

When we first learn to weave we usually are taught to tie up our treadles from left to right just as they are written in a typical draft. Traditionally, you would set up the treadles from left to right as they are written in the tieup: Treadle 1 2 Center 3 4 Lifting 12 23 34 41 Foot --Left-- --Right-- To weave this pattern, you would use your left foot to weave treadle 1 followed by treadle 2, then switch to your right foot to weave treadles 3 followed by treadle 4. Walking the treadles is a much more comfortable, ergonomic alternative to this. The treadles still lift the same harnesses in the same order in order to get the same pattern. The difference is that the treadles under the loom are not tied up from left to right. They are tied up so that you can “walk” the treadles left-right-left-right from the center out. Your odd numbered treadles will be on the left, even on the right.

Advantages to walking the treadles:

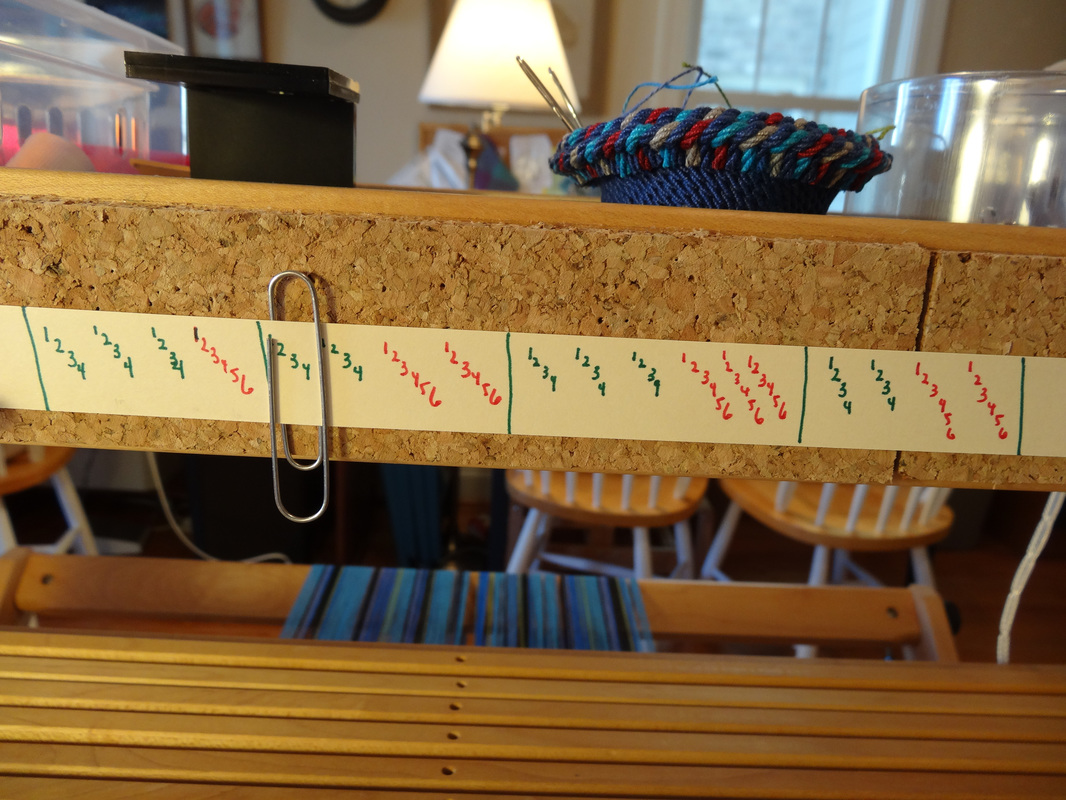

My Treadle Minder When weaving my Bronson Weave tieup, my left foot travels from treadles 1 to 2 and back, while my right foot travels down the pattern treadles 3,4,5,6,7,8,9 and 10. My feet are always treadling left right, left right. But my left foot is going 1-2-1-2-1-2 while my right is going 3-4-5-6-7-8-9-10. For my brain this is a little like patting my head and rubbing my tummy, and I have always had the tendency for my left foot to "wander" to treadle 3.

This would work well for any pattern where you left foot is working one set of treadles independently from your right. For example, I use the left 2 treadles for tie down treadles and the treadles to the right for pattern treadles in summer and winter.

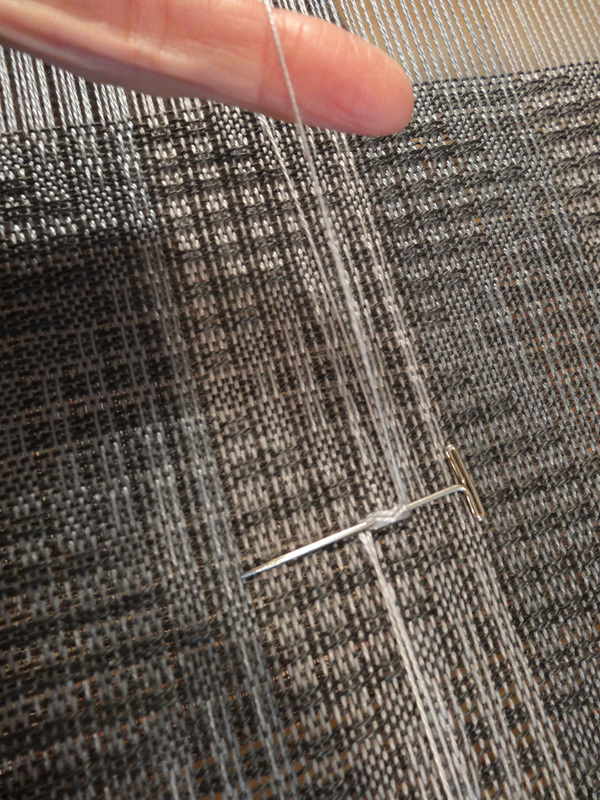

Consider this an Addendum to yesterday's post about my attempts to weave off 6 shawls for my son's wedding attendants. There was an additional adjustment to my weaving that I made midway through Shawl #1. Once I realized that the tencel was going to be "sensitive" and prone to breaking, I began misting the warp lightly with water every time I advanced the warp. The tencel experts of the weaving world have told me that tencel like to be wet and that keeping the warp damp (especially the selvedge threads) helps to strengthen the fiber. This can be especially helpful if you have to unweave tencel!

It should have been a no-brainer. Apparently not! I wound a 20 yard warp for 6 nice long shawls in stripes of light gray and silver 8/2 tencel. Each shawl was to be woven in a modified Bronson weave using a charcoal gray weft. I decided to weave several different treadlings so that the shawls for each young lady would be a little different.

The saga continues: I cut Shawl #1 off the loom and retied the warp to make sure I had perfect tension before beginning the next shawl. The selvedges in Shawl #2 were somewhat better, but I continued to have broken threads along the right selvedge as well as in two sections in the center of the shawl. By the time I cut the shawl off the loom, I had about 20 repairs to make, and more than a dozen of them were along the right hand selvedge. And I can assure you I do not enjoy making repairs in the finished cloth - especially along the selvedge edge!

I was shocked at how much this helped! The selvedges were great and I did not have a single selvedge thread break for the entire 95" length of the shawl. I still had threads break in the other two trouble areas of the shawl, confirming my belief that this batch of silver yarn was probably defective, under-plied in sections, or otherwise weakened for some reason. But just to be able to solve the problem on the selvedge was a huge relief! Three shawls down, three to go… Well the scarves are done, and you might be thinking that this seemed like a lot of work and a lot of days. I can assure you that it did not really take 9 days to make these 2 scarves.

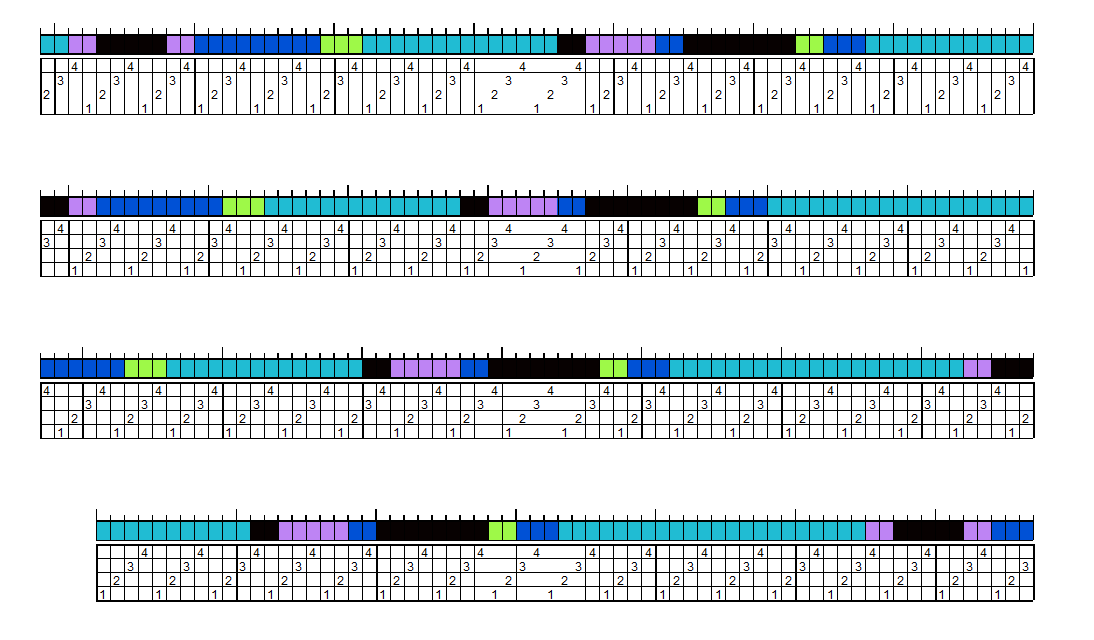

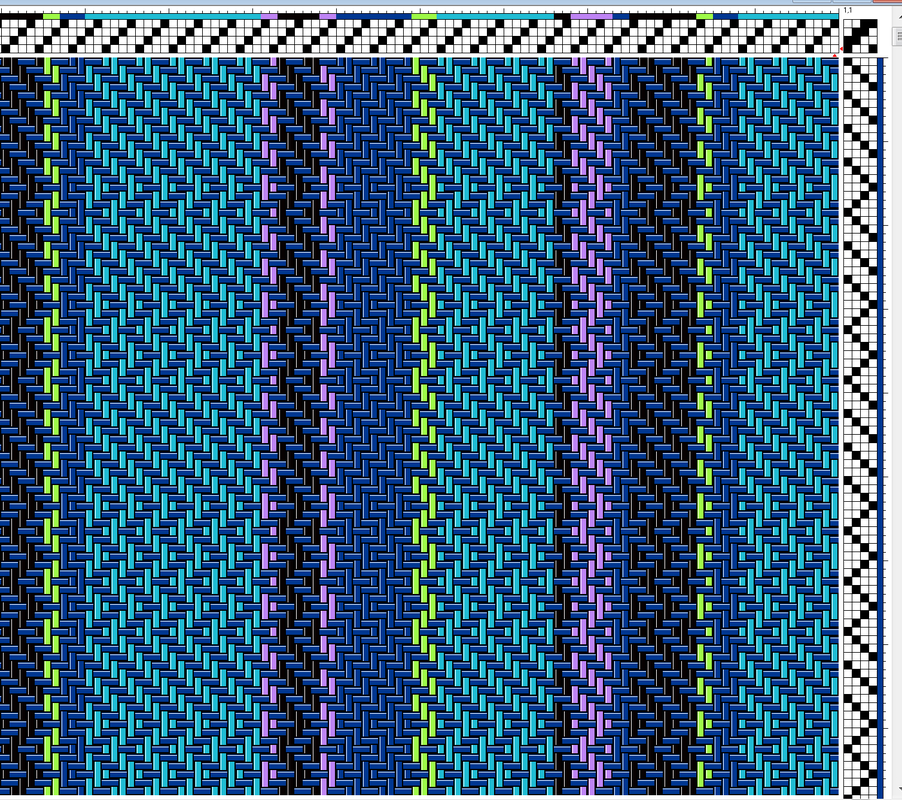

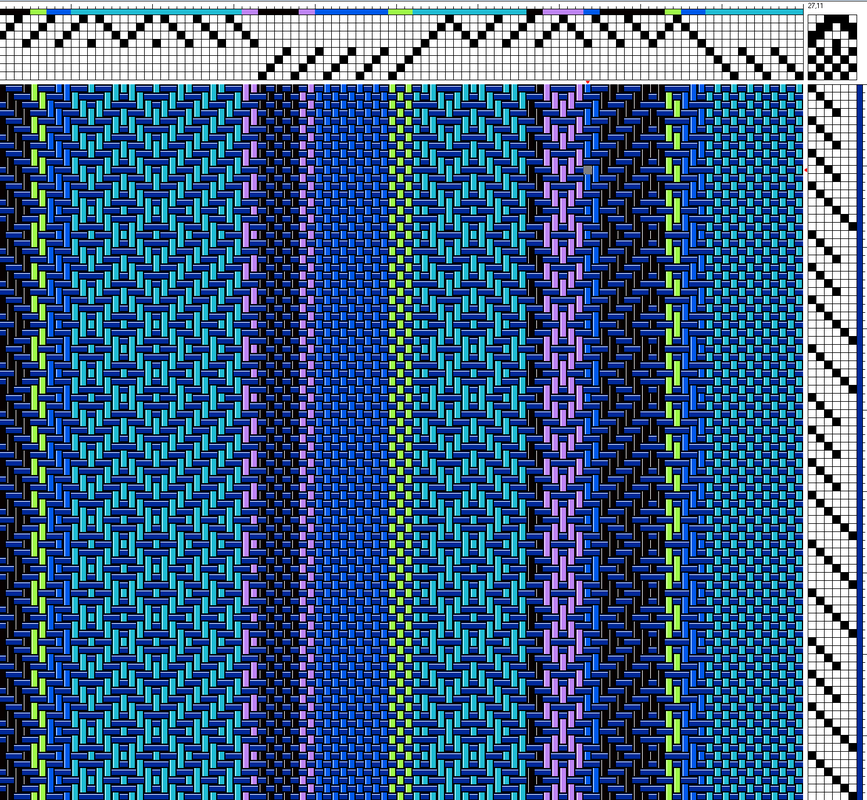

Four Harness Alternatives I have had a request for a draft for a similar scarf for those who only have a 4 harness loom. It is not possible to mix plain weave and twill in the same way with only 4 harness, but I have come up with a draft that uses the same bamboo warp in a twill, with a couple of possible options for treadling.

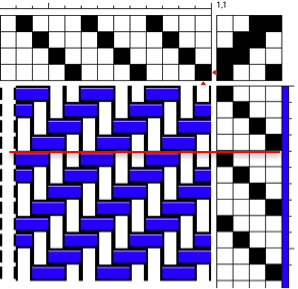

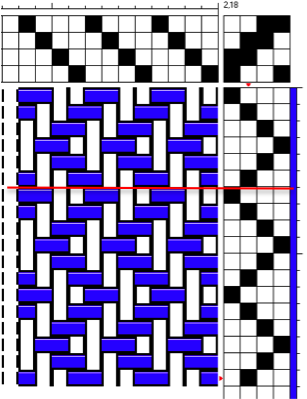

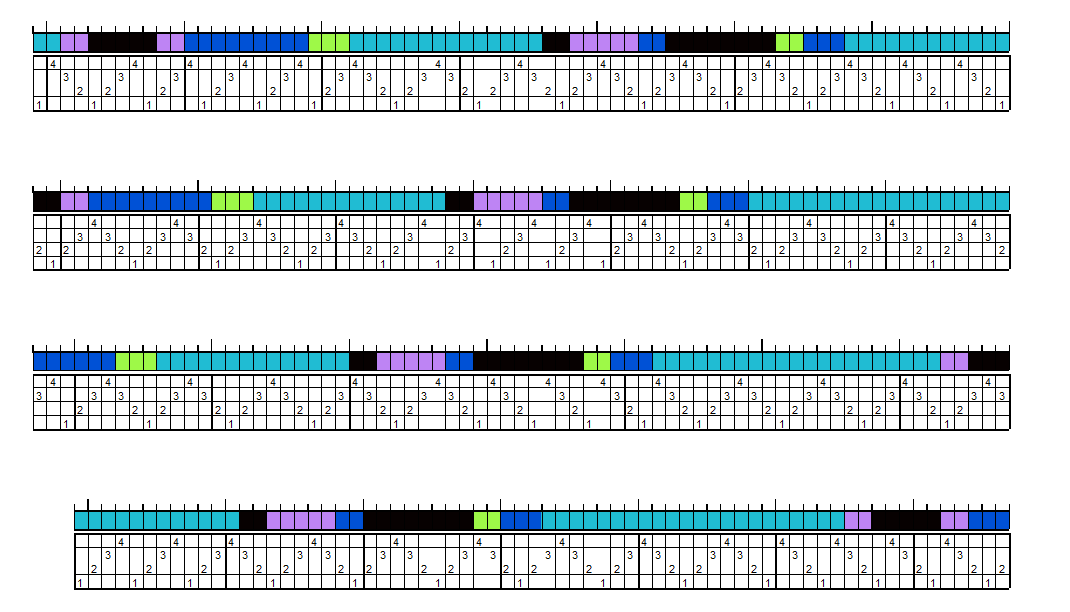

Alternative 1 This draft uses EXACTLY the same colorway and treadling as the scarves that I wove. It has 281 threads, just like the warp I used. It is a point twill threading, and I would recommend using a floating selvedge with this treadling. The draft is shown below, and a partial drawdown is shown to the right so you can see what the cloth would look like. Click on either photo to zoom in. Alternative 2 This draft uses the same colorway as the scarves I wove EXCEPT that the last group of aqua threads on the far left of the draft has 11 threads in it instead of 12, giving a total of 280 instead of 281. This allows for a multiple of 4 for the straight draw threading. You would not need a floating selvedge with this threading (as long as you start your shuttle from the right side). This draft uses the same treadling as the scarves that I wove. The draft is shown below, and a partial drawdown is shown to the right so you can see what the cloth would look like. Click on either photo to zoom in.

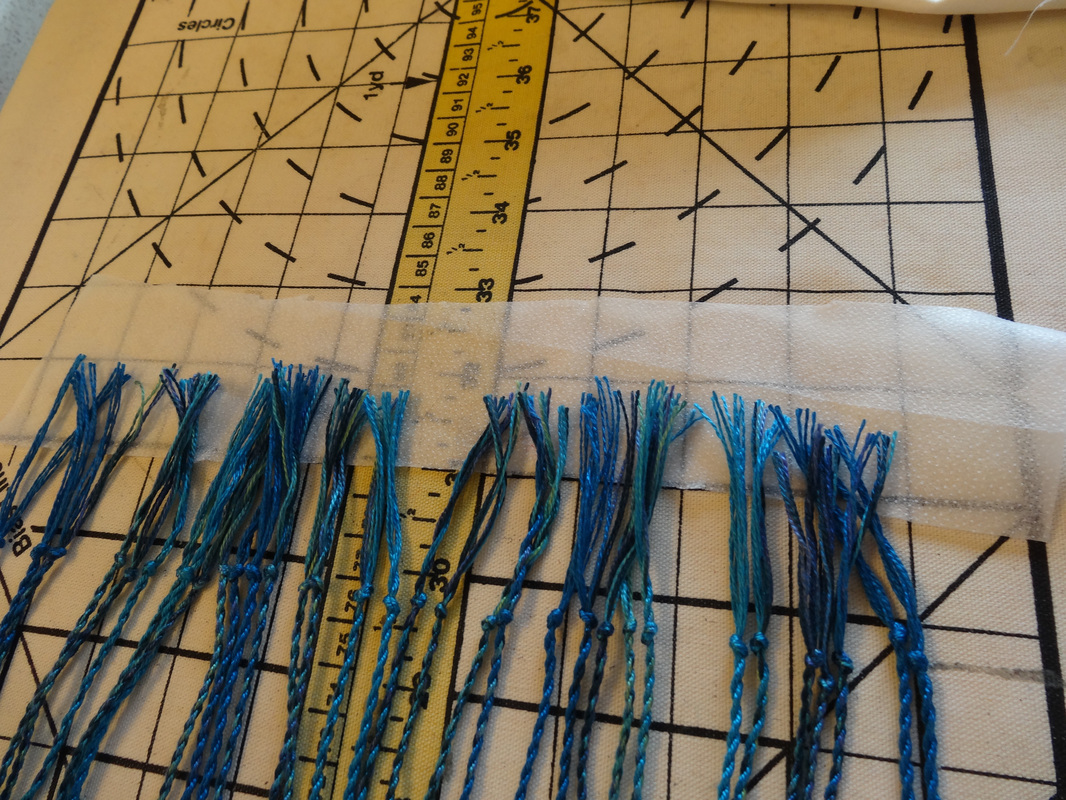

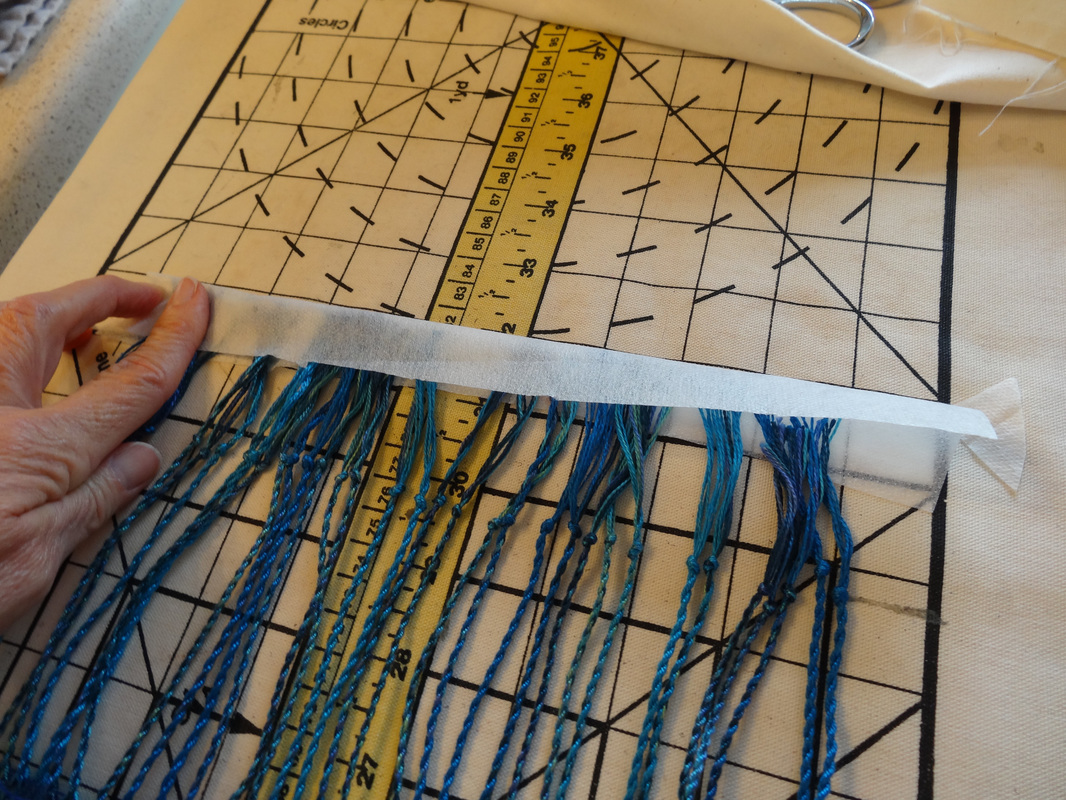

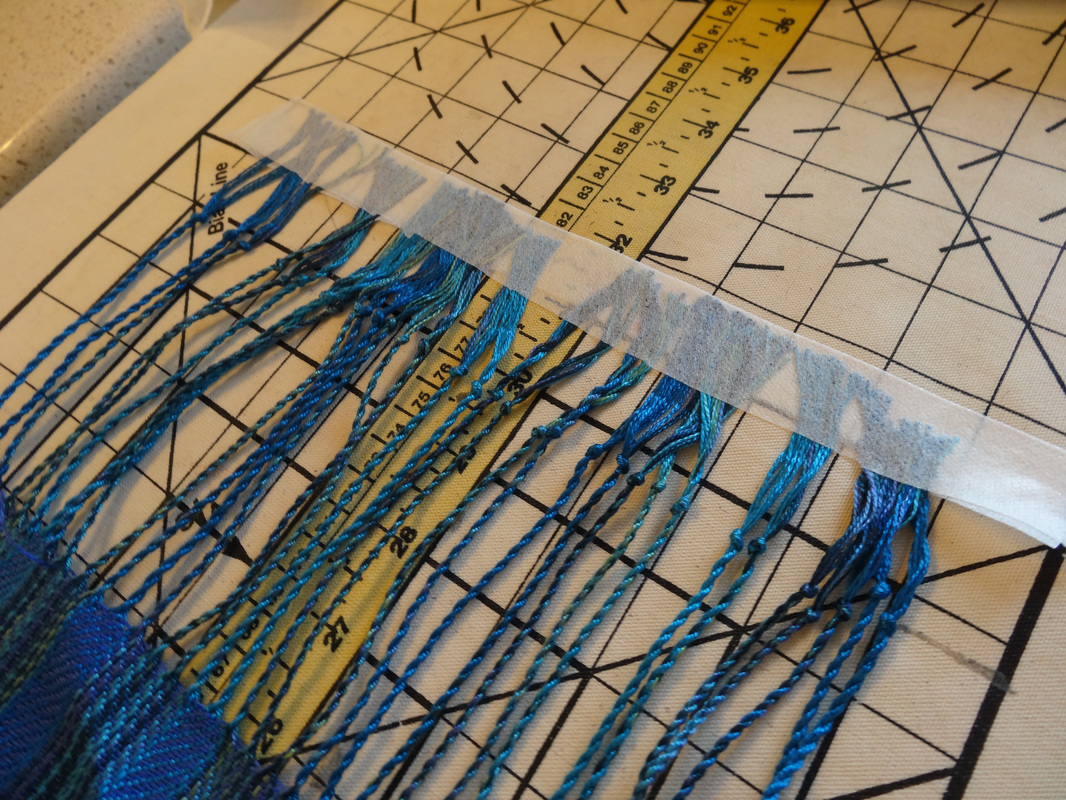

Wet finishing, pressing and trimming The final finishing took 5 steps (Note: My choice for wet finishing varies depending on the fiber and structure of the scarves. Bamboo and tencel scarves in twill and plain weave do very well with machine washing and drying)

To read my final thoughts on this project go to Life History-Final To review, go back to Life History-Day 8

Scarf #1

Once the scarves were woven it was time to finish them. Go to Life History-Day 9. To review, go back to Life History-Day 7

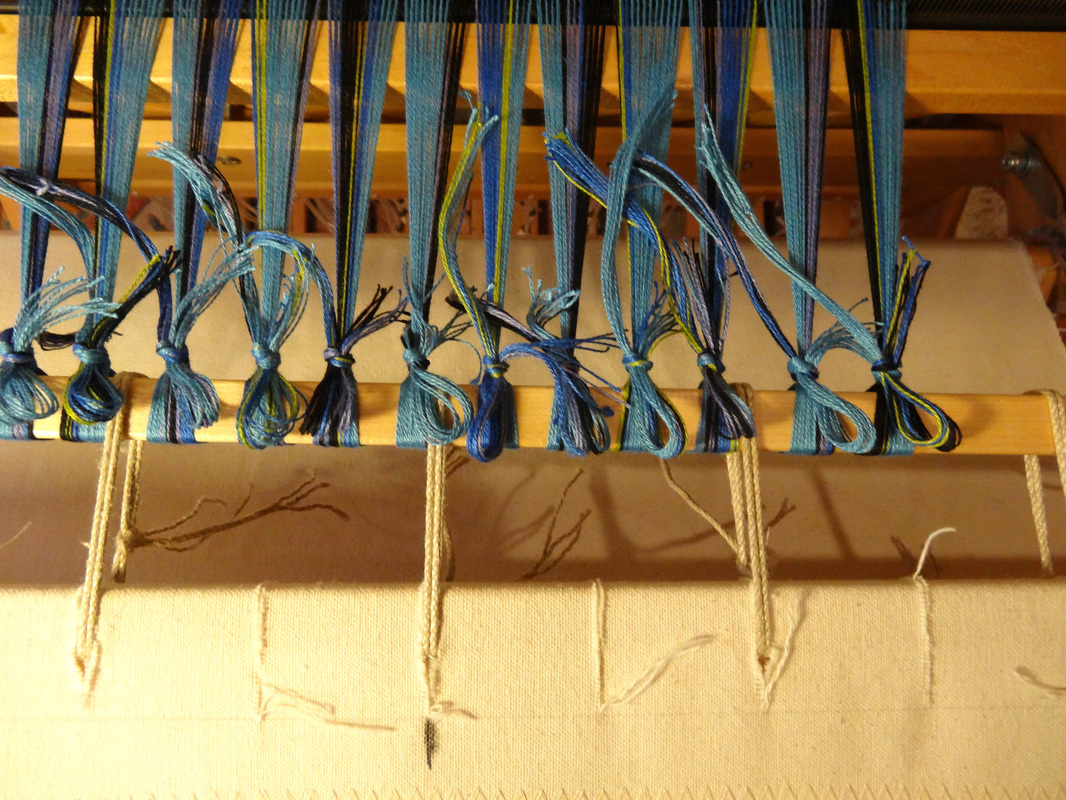

Tip: In the long run, sampling saves time and money! I wove 13" of samples, using 6 different wefts: royal 8/2 tencel, black 8/2 bamboo, iris 8/2 tencel, teal 8/2 bamboo, amethyst 8/2 tencel, and ming blue 8/2 tencel. Weaving in pattern, I got about 23 picks per inch (ppi). I cut the sample off the loom, tying the warp in slipknots in front of the reed to protect it before it gets retied to the front apron rod. I zigzagged across both ends of the sample, washed it in the washing machine in warm water and dried it in the dryer on a gentle cycle. I pressed the sample with a hot iron. Conclusion: I liked the hand of the fabric so no need to re-sett the warp. I liked 4 out of 6 of the weft colors and decided to weave the 2 scarves using the black bamboo and the blue ming tencel. Samples done. Now to weave the scarves! Go to Life History-Day 8. To review, go back to Life History-Day 6 Tying the warp to the front apron rod Before I even began this step, I removed the raddle and lease sticks from the back of the loom, and I removed the texsolv cords that were used to support the raddle, lease sticks and reed while winding on and threading.

Tying up the treadles The treadling is a point twill treadling and the original tieup required 4 treadles. I like “walking” my treadles.

Weaving a header

|

Pattie LambI have been happily weaving since my son was born in 1988. Archives

June 2023

Categories

All

|

RSS Feed

RSS Feed