|

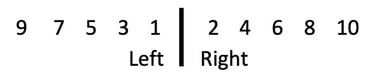

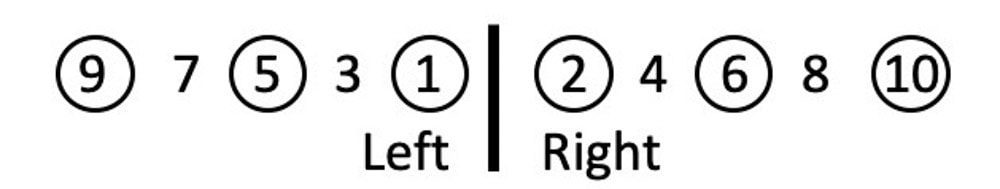

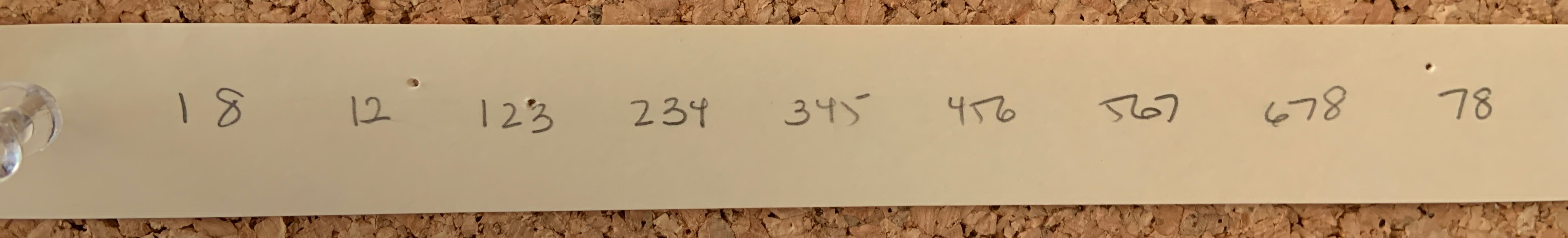

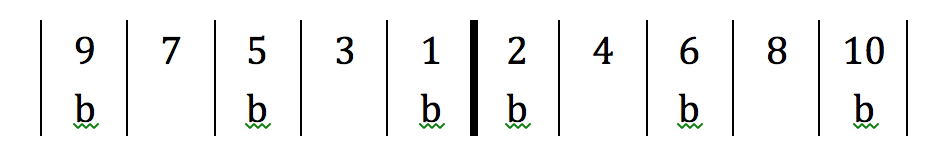

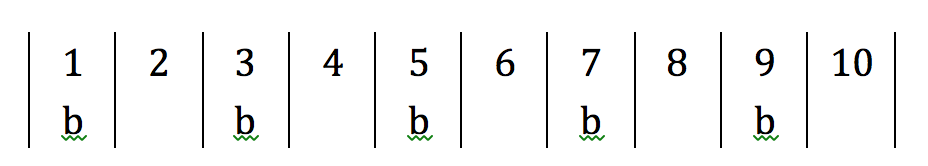

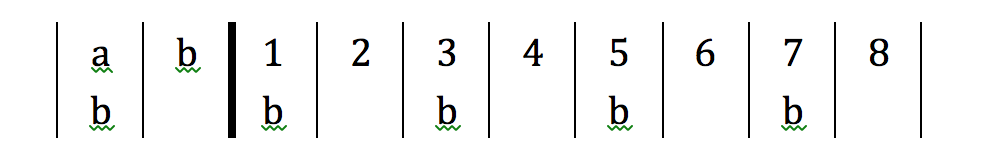

No Peeking Allowed - Treadling Tips Forgive me if I am repeating things I talked about in other posts, but some things bear repeating. Everyone handles their treadling differently, and that is just the way of weaving: everyone has their own way. Personally I hate peeking at my feet while I weave. I feel it disrupts my rhythm and flow. I do several thing to make sure I do not have to peek. Walking the treadles: I almost always walk my treadles. Inside to outside. I find it easy to walk left right left right as I treadle. My shuttle is (almost) always moving toward the foot that is depressed. This is ergonomically preferably to using one foot over and over. And it is surprisingly easy to manage walking the treadles with most treadling patterns. My treadles on a 10 treadle loom would be set up for walking as follows:

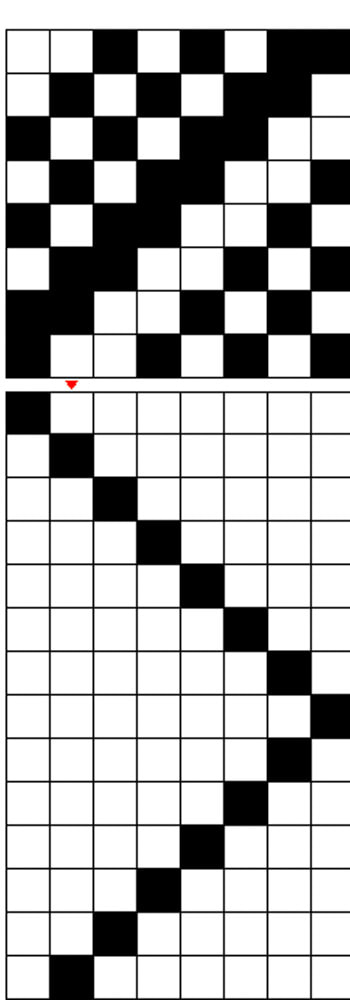

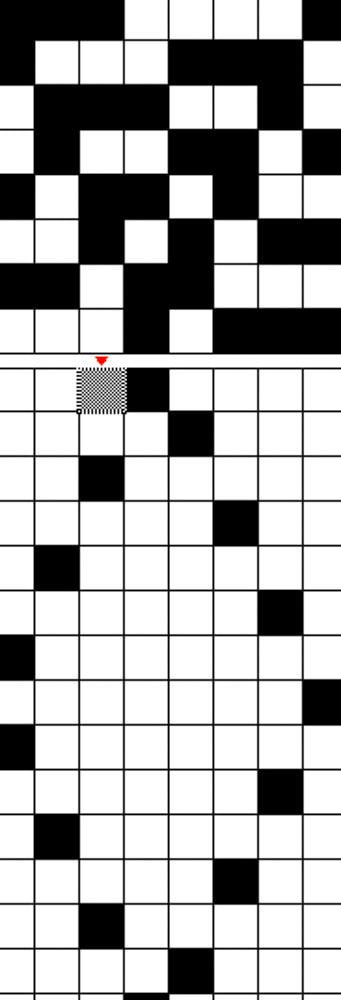

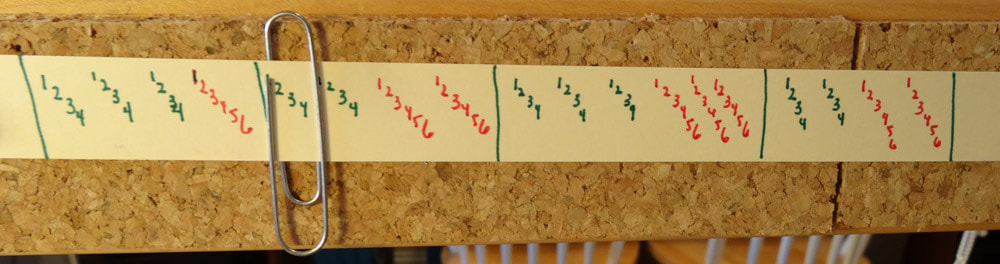

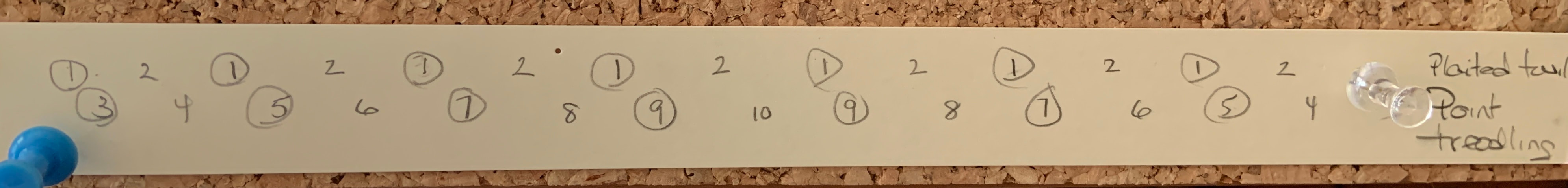

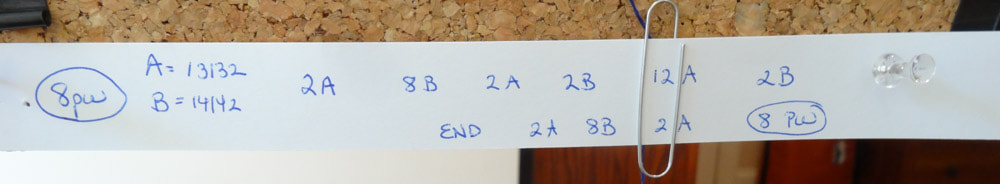

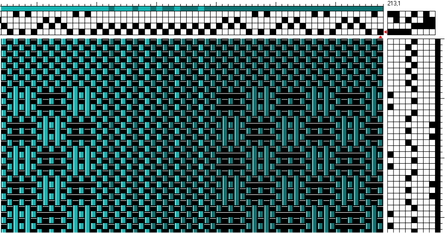

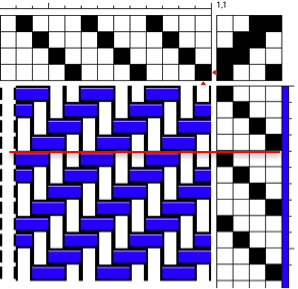

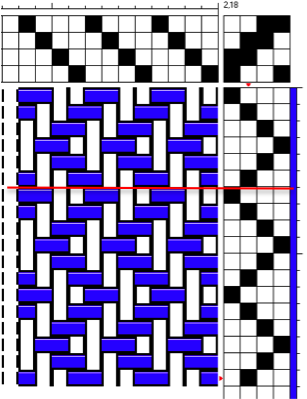

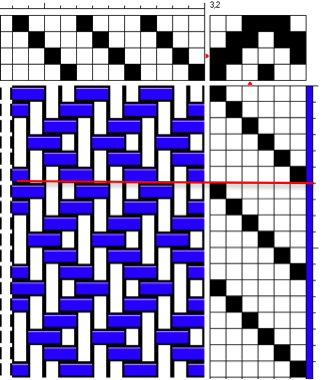

Examples of my cheat sheets:

0 Comments

Well, that is really questionable in my opinion. I have never enjoyed hemstitching. However, I have 2 really good tips to make it a little easier.

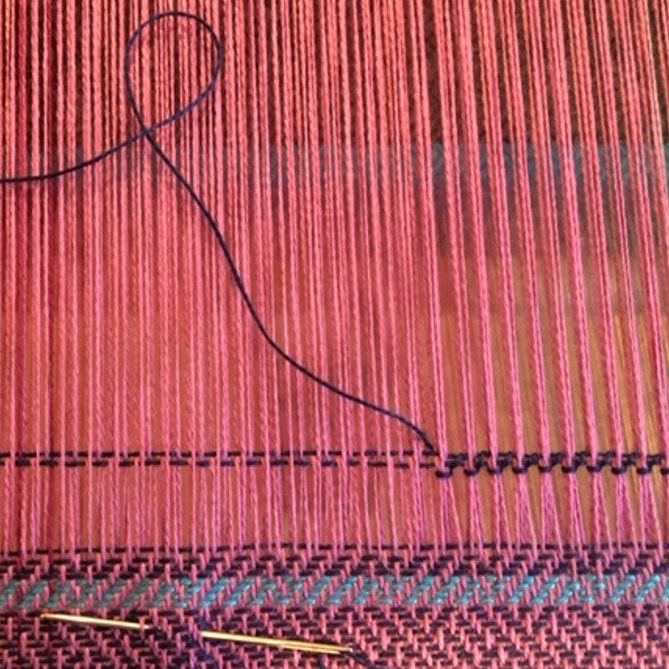

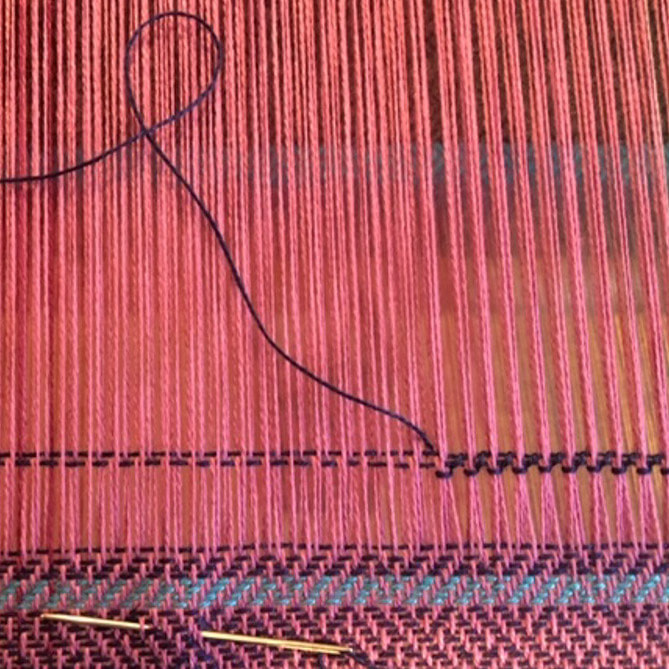

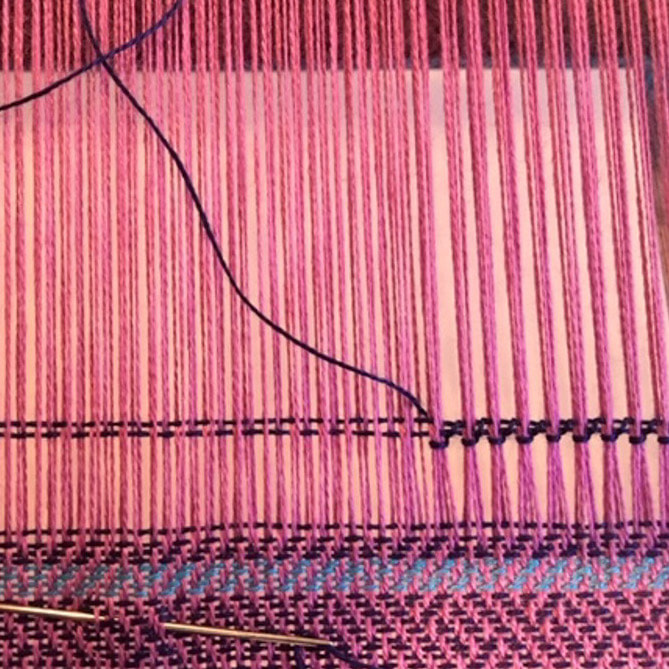

Tip 2: The second tip improves your visibility for hemstitching. Depending on the color of my warp, I find that seeing the warp ends and counting them correctly can be challenging. I place a contrasting sheet of paper UNDER the warp, and voila: visibility improves dramatically. Over the years I have gathered many tools that have become indispensable to me in my studio. Here are a few that are easy to find online.

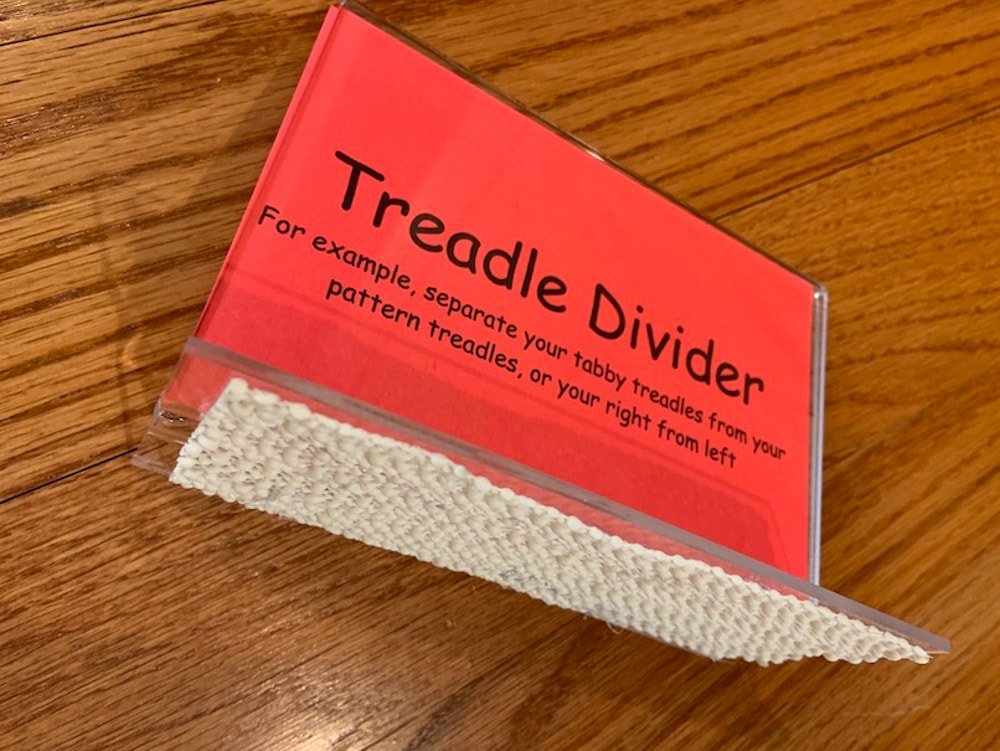

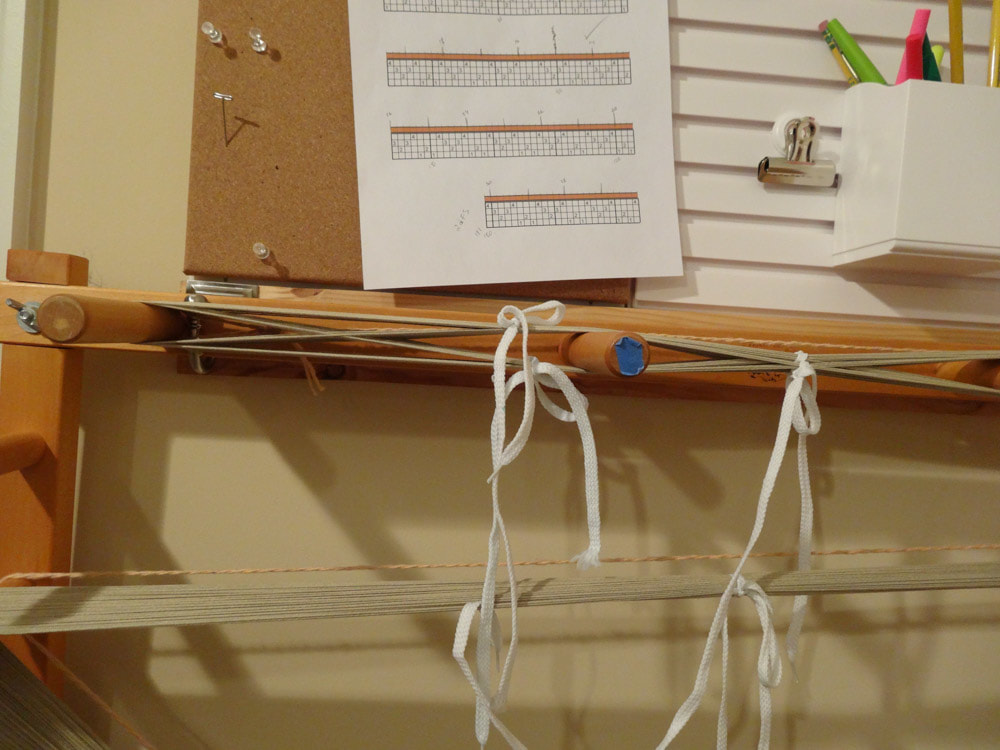

Treadle Bands Goody Girls Ouchless Elastics, 2 mm, No metal Target or Amazon, various counts and prices I use these on my treadles so I can treadle without peaking: “Braille” for my feet. I put them on all of my treadles and slide certain ones down so my feet can feel them and others up out of the way so I cannot. I like to put 3 on each treadle so they are "bulkier" and easier to feel with my feet.

There were only three possibilities (all cats):

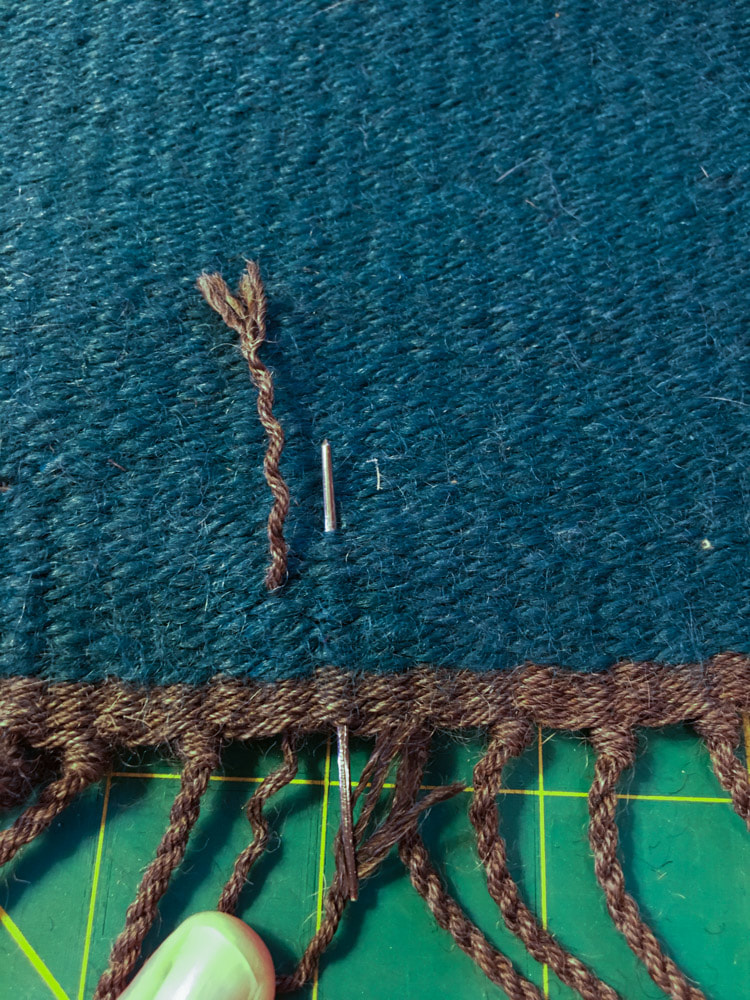

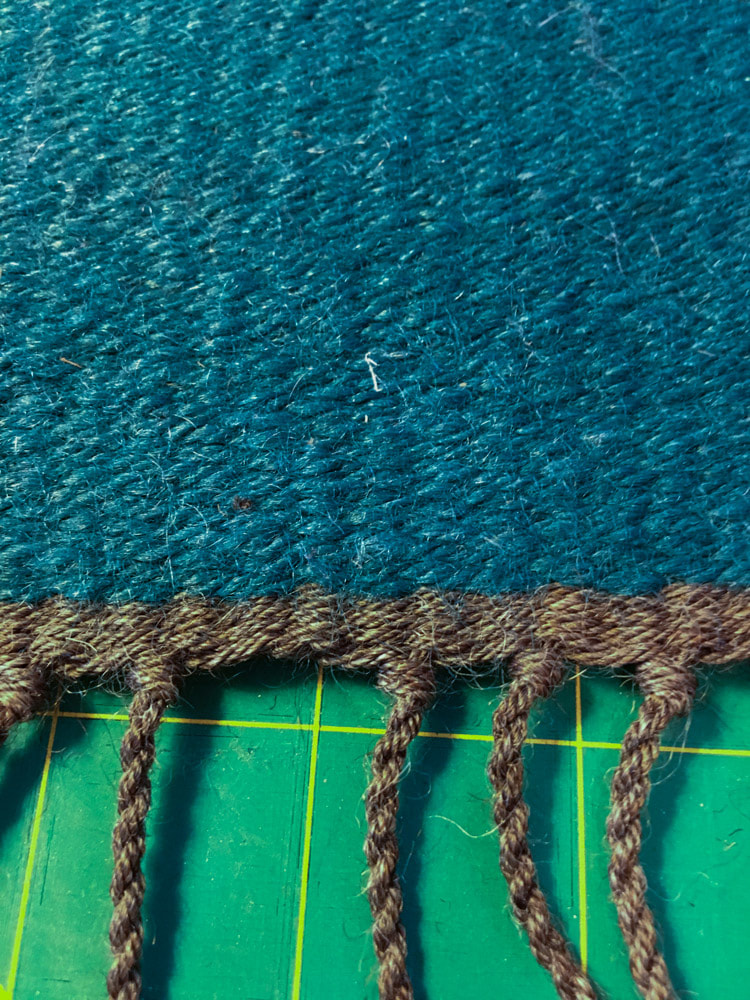

So Lizzie was found guilty by a process of elimination. I pulled the rug up and growled and fumed for a few days while I debated what to do. Fully a year later, I finally got around to repairing this debacle. Fortunately, I still had some of the linen I used for the warp for the rug. And the structure of the rug was a simple plain weave. A photo journal of the steps for replacing the fringe follows. The basic steps are:

What a relief to finally have this little project done and the rug repaired. I have missed having it at my front door.

I have long used rubber bands on my treadles to mark my path and help me treadle without peeking. It is a great tip. But I go through rubber bands like they are water because they dry rot very quickly. And they are hard to roll up and down the treadles between projects.

Walking the treadles: I tend to walk my treadles from the center out whenever my pattern allows me to do so. When I do that, I will put bands on the two center treadles so I can find my way back to center without peeking. I also place bands on every other treadle going out from the center. Treadling straight across: On the rare occasion that I tie up my treadles straight across, I simply put bands on the odd treadles and leave the even numbered treadles naked. Treadling pattern with tabby If I have 2 tabby treadles and a group of pattern treadles, my personal preference is to have the tabby treadles on one side and the pattern treadles on the other. If the tabby treadles are on the left, I will put a band on tabby a and leave tabby b naked. I will then put bands on all of the odd numbered pattern treadles and leave the even numbered pattern treadles naked.

Remember: You can click on any picture to zoom in!

Step 2: I gathered the tools I would need for repairing the broken warp threads The warp used in this rug was 8/4 cotton rug warp used double, and luckily I still had some on hand (this will not surprise anyone who knows me and has seen my yarn stash). So now all I need was a tapestry needle threaded with a doubled strand of the warp thread and a little patience. The weaving should be easy because the rug was woven in plain weave. Step 3 - Fixing the Broken Threads

All done! And I think the rug looks better with short fringe anyway.

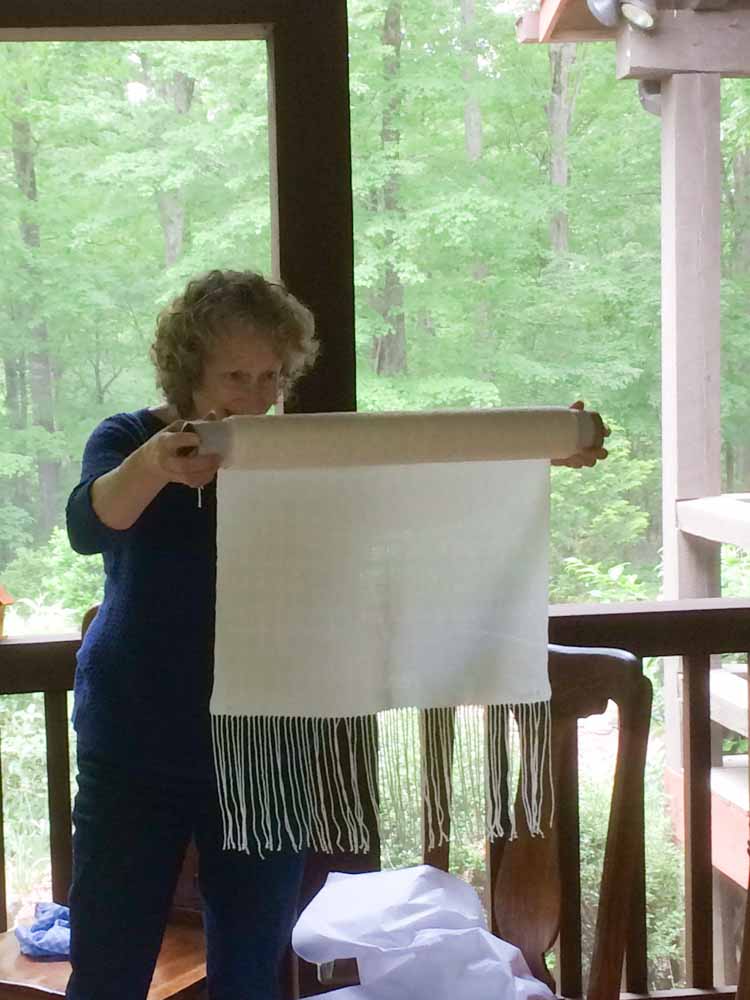

The Bride's Shawl

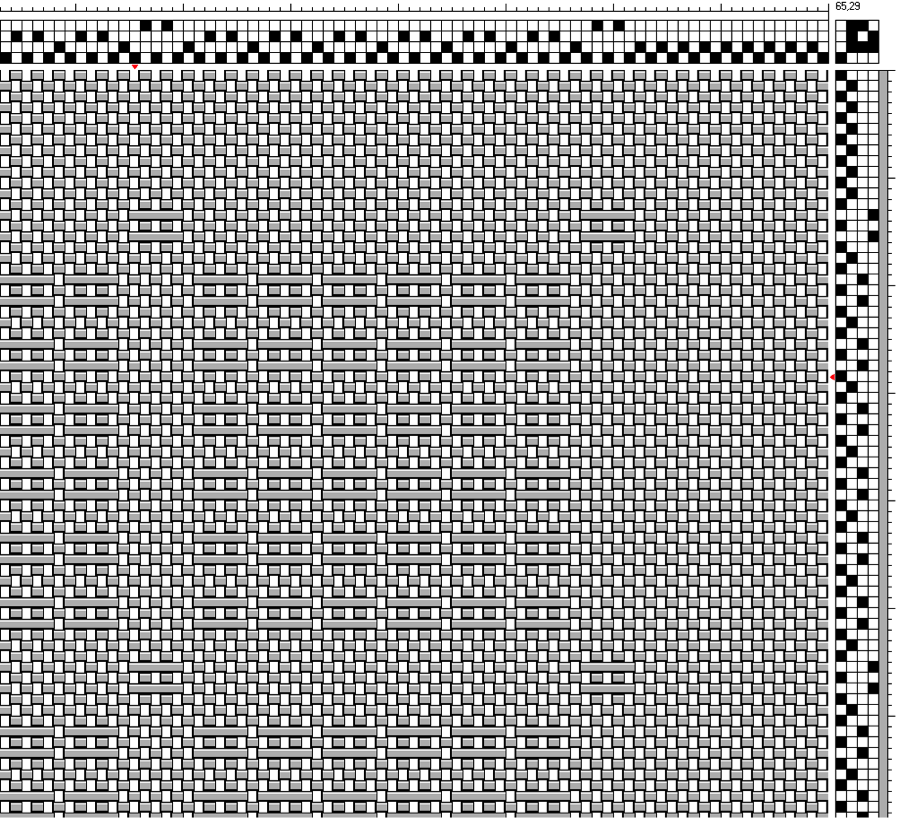

So the warp for two shawls went on the loom: one for the bride and one for a gift our outgoing guild president, Janice. A dozen of our guild board members took turns in April weaving off the first shawl so that we could present it to her at the May board meeting. I wove the bride's shawl off in May.

Next... Shawls for the Wedding PartyI offered to weave shawls for each of the four bridesmaids and my daughter, the "best sister". I put on a warp for 6 shawls: 5 for the wedding party and an extra:

Next... A Shawl for the Mother of the BrideThis shawl was a little more of a challenge. Or at least it caused me a little more angst. Mostly because I only had a photograph of Jamie's dress. So after exchanging photos and yarn samples, I finally decided on a huck lace shawl in 2 shades of teal, charcoal gray and mauve in the warp.

Again, I wove 2 shawls: the first I wove with the greyed teal for the mother of the bride., and the second with the dark teal to sell. Finally... Pocket Squares for the Groom and the DadsI really wanted to weave a pocket square for my son, but I wasn't sure if I would have time and I wasn't sure exactly what would work. After sampling quite a bit with 60/2 silk, I settled on a very simple plain weave square with some burgundy stripes on 2 sides and hemmed on 4 sides. I made 4 squares: 1 for Ryan, 1 for each of the Dads and 1 extra. And What Did I Wear?

When we first learn to weave we usually are taught to tie up our treadles from left to right just as they are written in a typical draft. Traditionally, you would set up the treadles from left to right as they are written in the tieup: Treadle 1 2 Center 3 4 Lifting 12 23 34 41 Foot --Left-- --Right-- To weave this pattern, you would use your left foot to weave treadle 1 followed by treadle 2, then switch to your right foot to weave treadles 3 followed by treadle 4. Walking the treadles is a much more comfortable, ergonomic alternative to this. The treadles still lift the same harnesses in the same order in order to get the same pattern. The difference is that the treadles under the loom are not tied up from left to right. They are tied up so that you can “walk” the treadles left-right-left-right from the center out. Your odd numbered treadles will be on the left, even on the right.

Advantages to walking the treadles:

My Treadle Minder When weaving my Bronson Weave tieup, my left foot travels from treadles 1 to 2 and back, while my right foot travels down the pattern treadles 3,4,5,6,7,8,9 and 10. My feet are always treadling left right, left right. But my left foot is going 1-2-1-2-1-2 while my right is going 3-4-5-6-7-8-9-10. For my brain this is a little like patting my head and rubbing my tummy, and I have always had the tendency for my left foot to "wander" to treadle 3.

This would work well for any pattern where you left foot is working one set of treadles independently from your right. For example, I use the left 2 treadles for tie down treadles and the treadles to the right for pattern treadles in summer and winter.

Consider this an Addendum to yesterday's post about my attempts to weave off 6 shawls for my son's wedding attendants. There was an additional adjustment to my weaving that I made midway through Shawl #1. Once I realized that the tencel was going to be "sensitive" and prone to breaking, I began misting the warp lightly with water every time I advanced the warp. The tencel experts of the weaving world have told me that tencel like to be wet and that keeping the warp damp (especially the selvedge threads) helps to strengthen the fiber. This can be especially helpful if you have to unweave tencel!

|

Pattie LambI have been happily weaving since my son was born in 1988. Archives

June 2023

Categories

All

|

RSS Feed

RSS Feed